High frequency curved plywood press applies high frequency generator to hydraulic press, by mold and electro, it transfers the high frequency power to the work piece to achieve the function of fast gluing and forming. It’s suitable for BENT PLYWOOD CHAIR, BENT OR ARC PLYWOOD FOR THE FURNITURE OR BED or other bent plywood products like CLOTH HANGER OR SURFACE OF MUSICAL INSTRUMENT.

1.Character of High Frequency Curved Plywood Press

A.Fast and uniformly heating

B.Bending shape is stable, not easy to change de-lamination.

C.High frequency power is a selectively heatig power, it concentrates only on water or glue. wood cannot consume high frequency power, so it is effective and power saving.

D.Wooden or MDF mold used, much economic than metal mold if shape is frequently changed.

| Power | 380V, 3Phase, 4Wire,50Hz |

| Total hydraulic pressure | 140 ton |

| Vertical hydraulic pressure | 80 ton |

| Quantity of vertical hydraulic cylinders | 2 pieces |

| Horizontal hydraulic pressure | 60 ton |

| Quantity of horizontal hydraulic cylinders | 2 pieces |

| Working size | 1600*800mm |

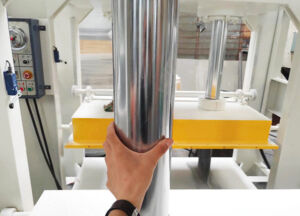

| Opening between up and down platen | 1735mm |

| Vertical Hydraulic cylinder stroke | 900mm |

| Opening between left and right platen | 1790mm |

| Horizontal Hydraulic cylinder stroke | 500mm |

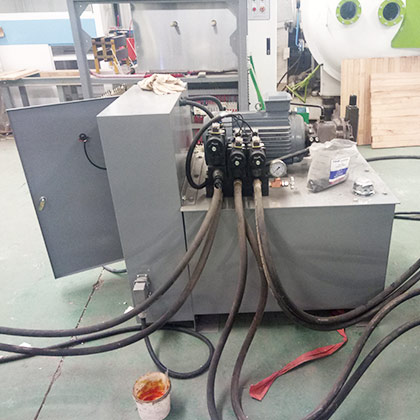

| Hydraulic system rated pressure | 25Mpa |

| Overall size | (L*W*H) 3900*900*3730mm |

| Weight | 6000kgs |

Machine Details

Bent Wood Samples

The Wooden Mold

Packing And Shipping

FAQ

1.How about the press table size?

Our standard size are 1600x800mm and 2500x1300mm.Customized size is also available.

2.What are included in 1 set machine?

The working type of the machine is “one drive two”,that means one set HF generator drives two sets hydraulic press machine.

3.What is the material of the mold?

It is wood.

4.How long does it take to press one chair seat?

For standard small chair,it wil take around 3-4 minutes.